NeoMag technology – oil filter – innovative and highly effective engine protection

The oil in a combustion engine is to provide lubrication of moving points of contact, and its respective properties (defined by standards ASE, or API) allow choosing it depending on operating conditions. However, the oil is contaminated during operation, resulting from the mixing of unburned fuel particles produced during the chemical processes, generated during combustion, and the mixing of metal particles. To ensure the high quality of lubricant throughout the service life, the main oil line is fitted with a filter whose task is to absorb these harmful substances. The principle of operation is based on the flow of oil through the membrane – made of a suitable cleaning paper with added synthetic resin-impregnated fibers – on which the dirt is deposited. The problem, however, is the purification of oil of fine metal particles.

Filter contamination

Every oil filter is subject to wear, as testified by the deterioration of the viscosity of the agent responsible for lubricating the engine. Filter contamination reduces the throughput of the perforation in the membrane, which makes the oil pass it unfiltered, through the sweep valve (safety valve in the main oil line), and goes forward. The result may be increased fuel consumption, decreased engine performance and, in extreme cases, its damage. At this point it is worth paying attention to the metal particles in the lubricant. They are a natural factor arising in case of worsened lubrication by the friction of the friction elements, such as the pan – the shaft, or piston rings – the cylinder. And since during the start-up of a cold engine, the lubricant flow is always hindered, only the user and their driving style in the first stage of the travel determines the amount of the resulting metal particles that get into the oil circuit. Given their size, it is natural that the filter cartridge is contaminated quickly – which reduces the properties of the oil filter.

Is there a way to solve this?

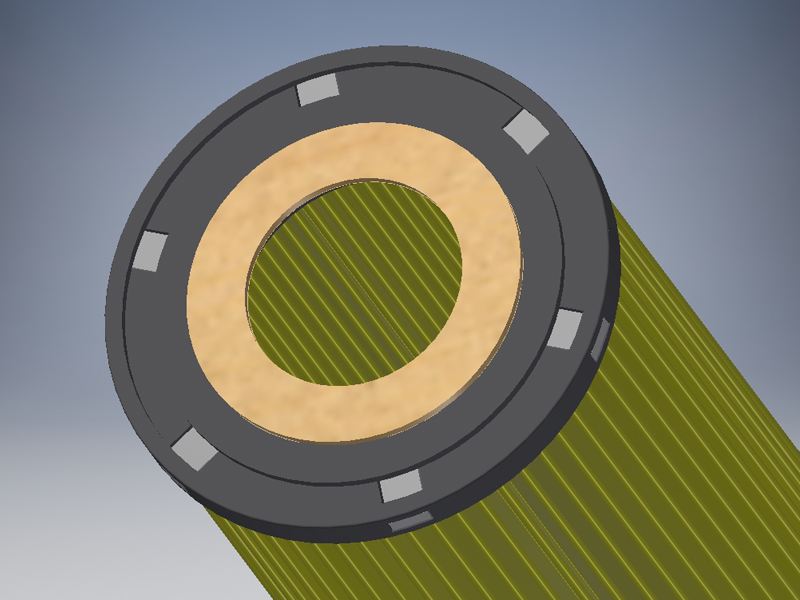

It turns out there is, and it is very simple. Master Sport laboratories have developed the innovative NeoMag technology, which allows increasing the working efficiency of oil filters. The filter made in NeoMag technology uses a neodymium magnet, which eliminates the problem of metal particles moving in the oil. The neodymium magnet is a permanent magnet made from a combination of neodymium, iron and boron. It is made by compressing powdered components in a magnetic field at elevated temperatures. These magnets produce a very strong magnetic field, which corresponds to the strong force of attraction (around 10 x stronger than traditional magnets). If such a magnet is attached to the filter housing (in spin-on filters), or to the outer ring of the membrane (in the case of replaceable cartridges), the metal particles are “caught” from oil and attracted to one place.

The result?… longer, cheaper, safer

The use of such devices allows not only the purification of oil as in conventional filters (the membrane is made of standard materials used by recognized manufacturers), but also capturing particles, which normally block the filter, reducing its quality. Thus, by increasing the efficiency of the filter, the lubricity of the agent is prolonged, and… we may feel confident that the engine will not fail.

Who is the filter good for?

This innovative Neomag technology is addressed to all drivers, since the pros include more efficient filtration, prolonged life of the filter membrane, and many times higher motor protection. However, there are three groups of drivers for whom this solution is particularly appropriate:

Owners of new cars with modern petrol engines

The downsizing trend currently prevalent in the automotive industry, consisting in offering engines with small displacement, which are equipped with a turbocharger, forces greater attention to these engines. After all, while the crankshaft revolves around 6000-8000 rev/min, the boost turbine can achieve the speed of 250,000 rev/min. Thus, any dirty oil (and the turbocharger shaft is part of the main oil line and is lubricated with engine oil) may damage the bearings of the turbine, so that the service life will be shortened. The filter in the Neomag technology (Master-Sport Automobiltechnik (MS) GmbH) protects the turbocharger, giving it a longer life.

Owners of new diesel cars

The introduction of common rail injection has completely changed the perception of diesel engines. These are no longer cars whose main advantage was the low cost of operation and high torque. Currently, diesel models are in no way inferior, and often exceed the petrol variants. Hence, they are often purchased by people driving very dynamically. Since the diesel engine crankshaft rotates at a speed of about 5000-6000 rpm and the turbine shaft at a speed of up to 250 000 rpm, any oil contamination will have fatal consequences for the life of the engine. Hence the innovative NeoMAG technology ensures proper lubrication of all engine components.

Those looking for sporty driving

This is a group of people who frequently use high engine speed. Although they are aware of the need to ensure proper engine lubrication and buy high-quality oil and filter, this would never eliminate all threats. Apart from their elimination of harmful substances from the oil, NeoMAG filters also eliminate metal particles that are being “pumped” with the oil in the oil line while driving faster.